Livestock farms play a vital role in our food system, but manure management can create a significant environmental and financial challenge for farmers. Anaerobic digesters turn this waste into a valuable resource with economic, environmental, and energy benefits.

The U.S. Environmental Protection Agency’s (EPA’s) Livestock Anaerobic Digester Database offers a powerful tool for understanding the current landscape of anaerobic digestion technology. This article explores the key trends in digester adoption in the United States.

A Look at Anaerobic Digester Adoption in the U.S.

Data retrieved May 2024

To help visualize these valuable insights, we’ve created graphs based on the data, allowing you to explore key trends in digester adoption and potential benefits for your farm. Let’s delve into some of these key findings:

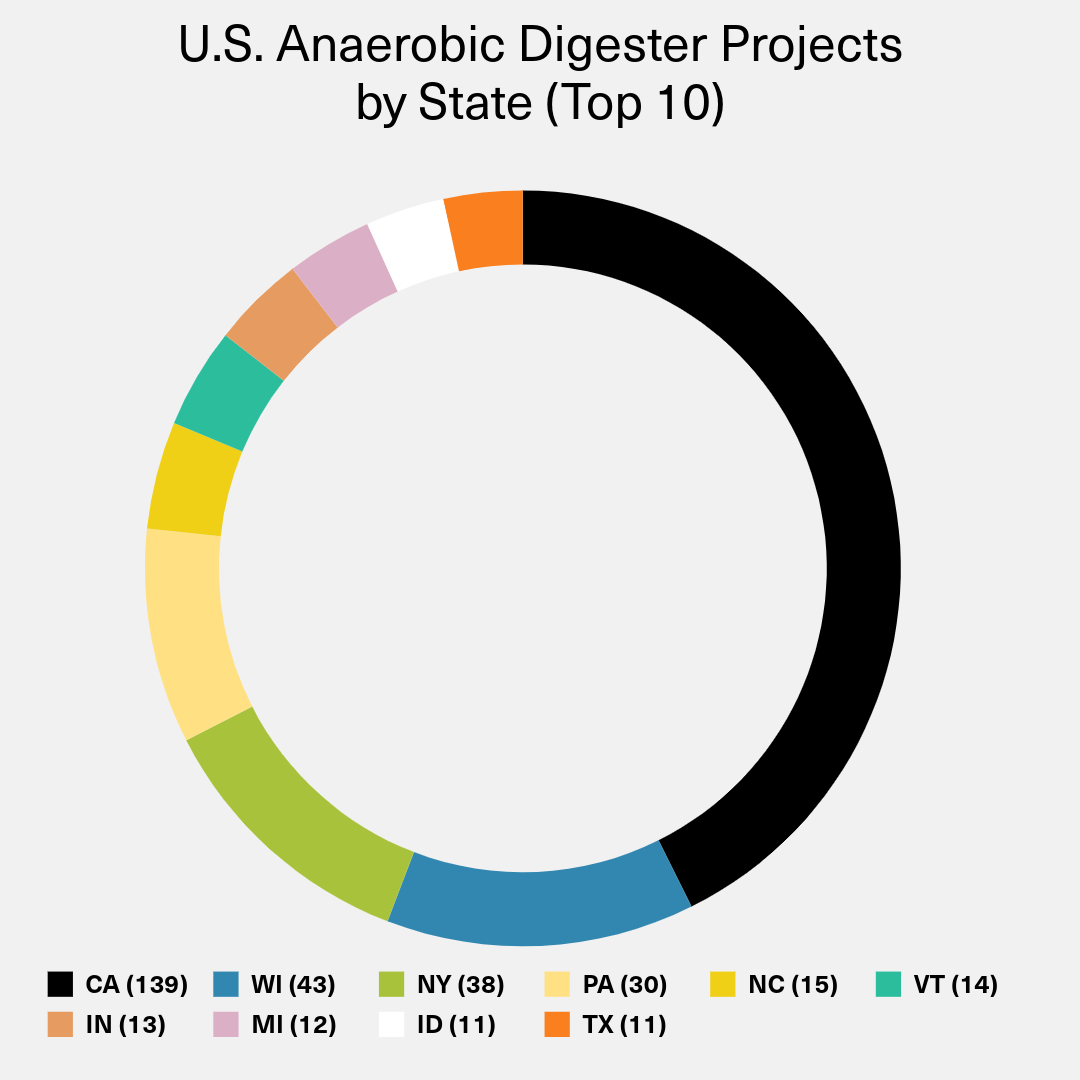

Geographic Distribution

This chart shows the distribution of digesters that are operational or under construction across the United States. California leads the way with 139, followed by Wisconsin (43), New York (38), Pennsylvania (30), and North Carolina (15). This information helps us understand regional trends in digester adoption and pinpoint areas with high potential for future development.

Several factors influence where digesters are located. Here are some key ones:

- Livestock Concentration: Areas with many large dairies often find digesters more economical due to the larger volumes of manure available.

- Regulations and Incentives: States with regulations or programs that favor renewable energy or waste management tend to see more digester adoption.

- Infrastructure: Access to pipelines for injecting biogas into the natural gas grid or existing electricity grids for power generation significantly impacts the feasibility of digester projects in a particular region.

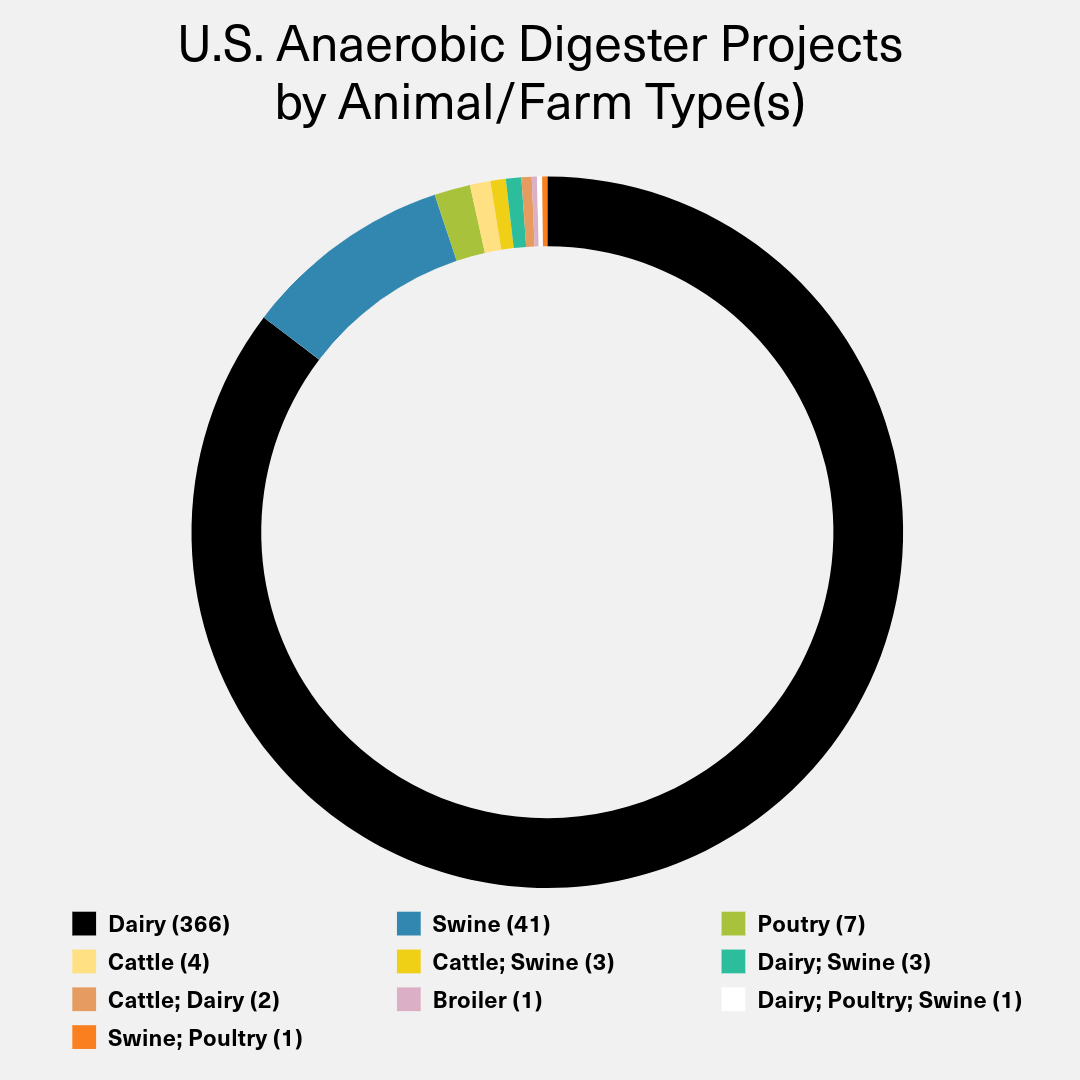

Animal/Farm Type

This graph breaks down the types of farms using digester technology. Dairy farms are the frontrunners, with 366 projects focused solely on dairy manure. Here’s why:

- Dairy Manure Advantage: Dairy manure naturally has a higher methane content than other livestock waste, making it more efficient for biogas production.

- Economies of Scale: Dairy farms often concentrate a larger number of animals, simplifying manure collection and management for digesters, making them more economically viable.

Swine farms follow closely with 41 projects. While currently lagging behind dairy, they represent a significant portion of the industry. Advancements in technology and potential economic incentives could lead to increased digester adoption in swine farms.

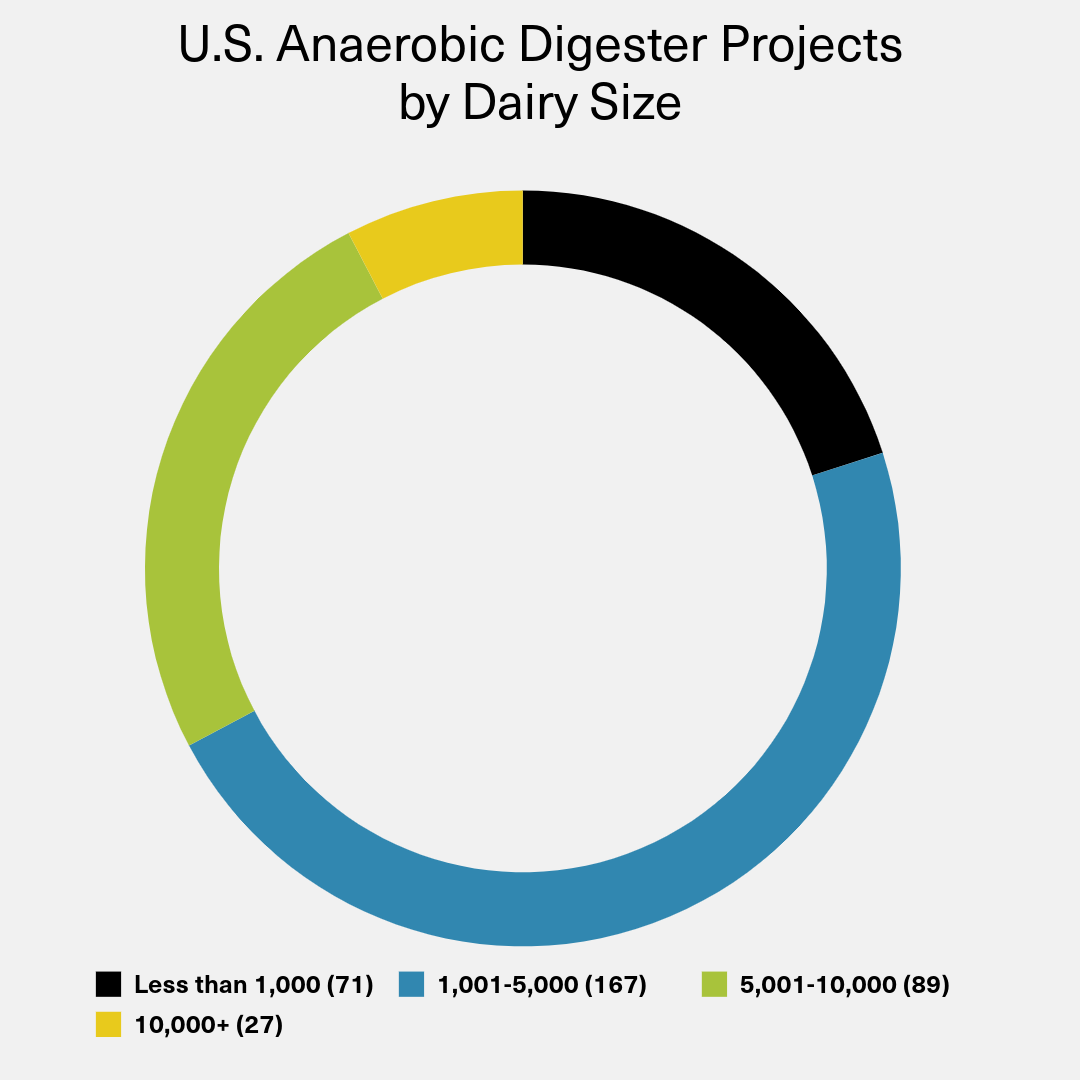

Dairy Size

This graph explores the size of dairy farms using digesters, categorized by the number of milking cows. Interestingly, medium-sized dairies (1,001-5,000 cows) lead the way with 167 projects. This suggests a potential “sweet spot” for cost-effectiveness. While large farms produce more manure, the upfront costs of installing and maintaining a digester system can be proportionally higher. Conversely, smaller farms may struggle to justify the cost with less waste available. Medium-sized dairies seem to strike a balance between manure volume and economic feasibility.

Large-scale operations (5,001-10,000 cows) follow with 89 projects. A significant number of smaller dairy farms (less than 1,000 cows) are also represented, with 71 projects. This indicates a positive trend towards broader adoption across the industry. As technology advances and potentially financial incentives become available, digesters may become more accessible for even smaller farms.

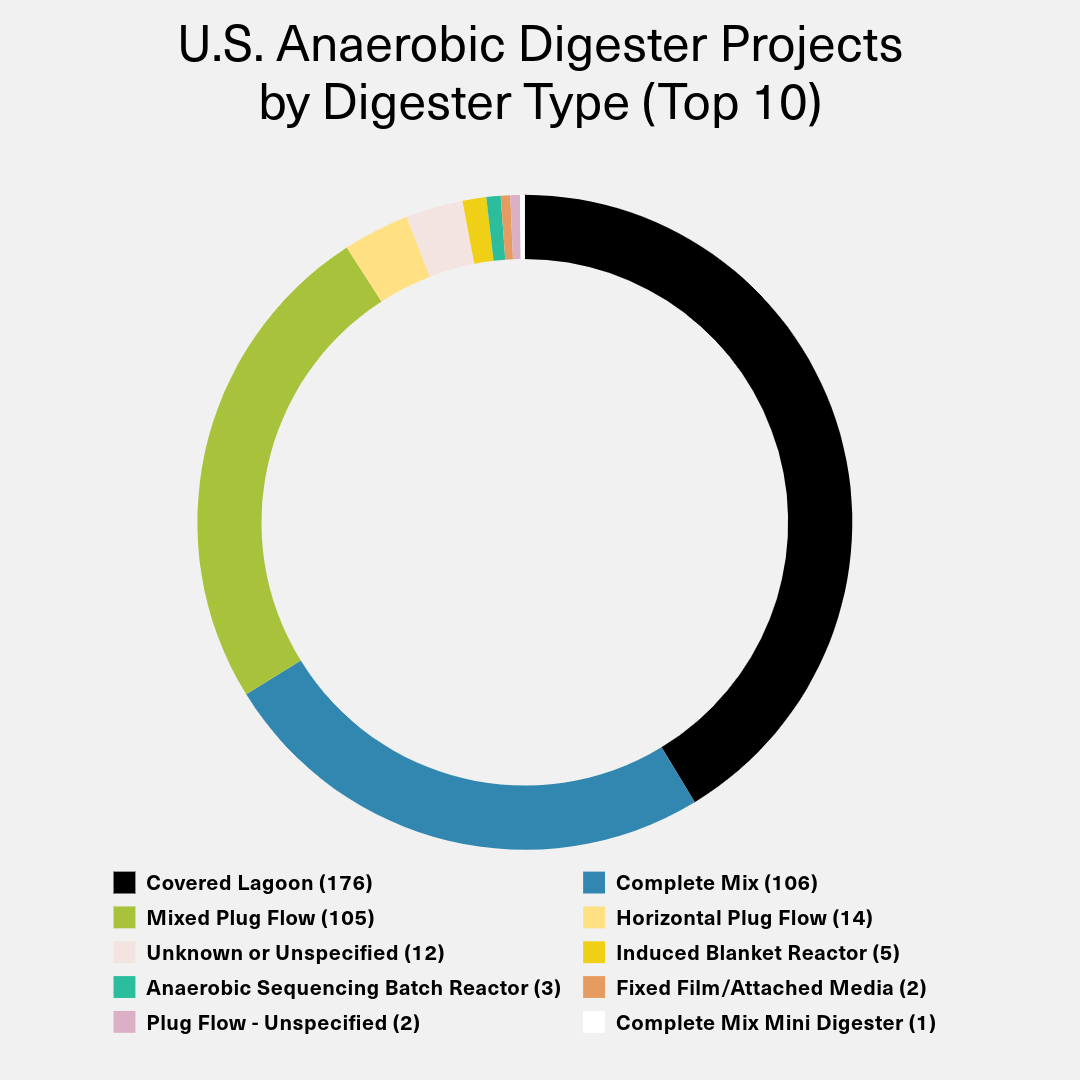

Digester Type

This graph explores the different digester options utilized by farms across the database. Covered lagoon systems take the lead with 176 projects, likely due to their lower upfront costs and simpler design. While a good starting point, they may not offer the optimal performance for all farms.

Complete mix digesters come in second with 106 projects. Offering a compelling alternative, these systems strike a good balance between affordability and performance thanks to features like better mixing and higher methane yields. This translates to potentially greater biogas production and increased profitability for your farm.

The variety of digester technologies reflects the evolving industry. As it matures, we can expect advancements and potentially new designs tailored to address specific needs and optimize biogas production from various waste streams.

Boosting Your Bottom Line

The Livestock Anaerobic Digester Database provides valuable insights into successful digester projects on farms similar to yours. Explore this information to see if a digester system aligns with your farm size, livestock type, and available government incentives. Remember, the database is a starting point. Further research considering these factors will help you make informed decisions for your farm’s future.

SKS Development is a leading provider of renewable energy solutions, helping you turn manure into a valuable resource. Our experienced team will work with you to understand your needs and develop a solution that meets your operational and investment goals, building the right facility for your farm.

To learn more about biogas and how it can benefit your dairy farm, please reach out to the SKS team. We would be happy to answer your questions and help you get started on your path to a more sustainable and profitable future.