Managing a dairy farm demands agility and innovation. In today’s dynamic agricultural landscape, optimizing efficiency and profitability requires embracing cutting-edge solutions. One such technology, anaerobic digestion, has garnered significant interest and has emerged as a viable path to resource optimization and revenue generation. This Q&A article aims to clarify the details of anaerobic digestion for the forward-thinking dairy operator.

We’ll dissect prevalent questions surrounding odorous emissions, operational distinctions from aerobic counterparts, feedstock compatibility, methane production, and, most critically, investment considerations. By dissecting these crucial aspects, we hope to clarify common misconceptions, illuminate the potential of anaerobic digestion, and empower you to make informed decisions concerning your farm’s future.

Do anaerobic digesters smell?

Anaerobic digesters offer a compelling solution for managing organic waste. These sealed, controlled environments harness the power of microbes to transform organic matter into valuable biogas and nutrient-rich digestate, delivering significant economic and environmental benefits. However, a common concern lingers: potential odor emissions.

While the potential for odor is a common concern surrounding anaerobic digestion, the reality is far more pleasant. Properly designed and operated, these innovative systems transform organic waste into valuable resources, significantly reducing odors compared to traditional waste management methods like open lagoons or landfills.

This odor mitigation stems from several key factors:

- Contained system: Anaerobic digestion occurs within a sealed tank, preventing the escape of odorous gasses and compounds.

- Biodegradation: The anaerobic digestion process itself breaks down organic matter into stable products, eliminating the breeding ground for odor-causing bacteria.

- Methane capture: Biogas produced by the digester is captured and utilized, preventing the release of methane, a gas that can also contribute to odors.

- Advanced odor control: Modern digesters incorporate advanced odor control technologies, such as biofilters and scrubbers, to further minimize any potential emissions.

The bottom line? With proper design, operation, and maintenance, anaerobic digesters can be a clean and odor-free solution for waste management and renewable energy production.

What is the difference between aerobic and anaerobic digestion?

Both aerobic and anaerobic digestion offer efficient methods for processing organic waste, but their approaches diverge significantly. Understanding these key differences empowers informed choices for sustainable waste management.

1. Oxygen Dependence:

- Anaerobic digestion: Occurs in oxygen-free environments in which specialized microbes decompose organic matter, generating biogas (methane-rich) and digestate (nutrient-rich residue).

- Aerobic digestion: Occurs when microbes readily consume oxygen while breaking down organic matter, primarily releasing carbon dioxide and water.

2. Processing Speed:

- Anaerobic digestion: A multi-step process involving diverse bacterial communities, resulting in a slower breakdown compared to aerobic systems.

- Aerobic digestion: Generally faster due to readily available oxygen, which accelerates microbial activity and organic matter decomposition.

3. System Design:

- Anaerobic digestion: Requires sealed, controlled environments to exclude oxygen and maintain optimal conditions for specific microbial populations.

- Aerobic digestion: Utilizes open systems with aeration equipment to continuously supply oxygen to the microbes.

4. Byproducts:

- Anaerobic digestion: Produces biogas and digestate. The biogas can be used to generate heat and power and to fuel vehicles, while the digestate can be used as a fertilizer.

- Aerobic digestion: Primarily produces carbon dioxide and water. The resulting compost can be used as fertilizer.

5. Environmental Impact:

- Anaerobic digestion: Captures and utilizes methane for energy production. Additionally, digestate application can improve soil quality and reduce fertilizer use.

- Aerobic digestion: Can release greenhouse gasses like nitrous oxide and methane, depending on the system and management practices.

The environmental benefits and resource recovery potential of anaerobic digestion make it an attractive technology for SKS facilities. This approach not only generates renewable energy from waste but also provides valuable digestate for soil improvement, making it a cleaner and more sustainable option.

What can you put in an anaerobic digester?

Anaerobic digesters can process a wide variety of organic materials, but not all materials are suitable. Here’s a breakdown of what you can and cannot put in an anaerobic digester:

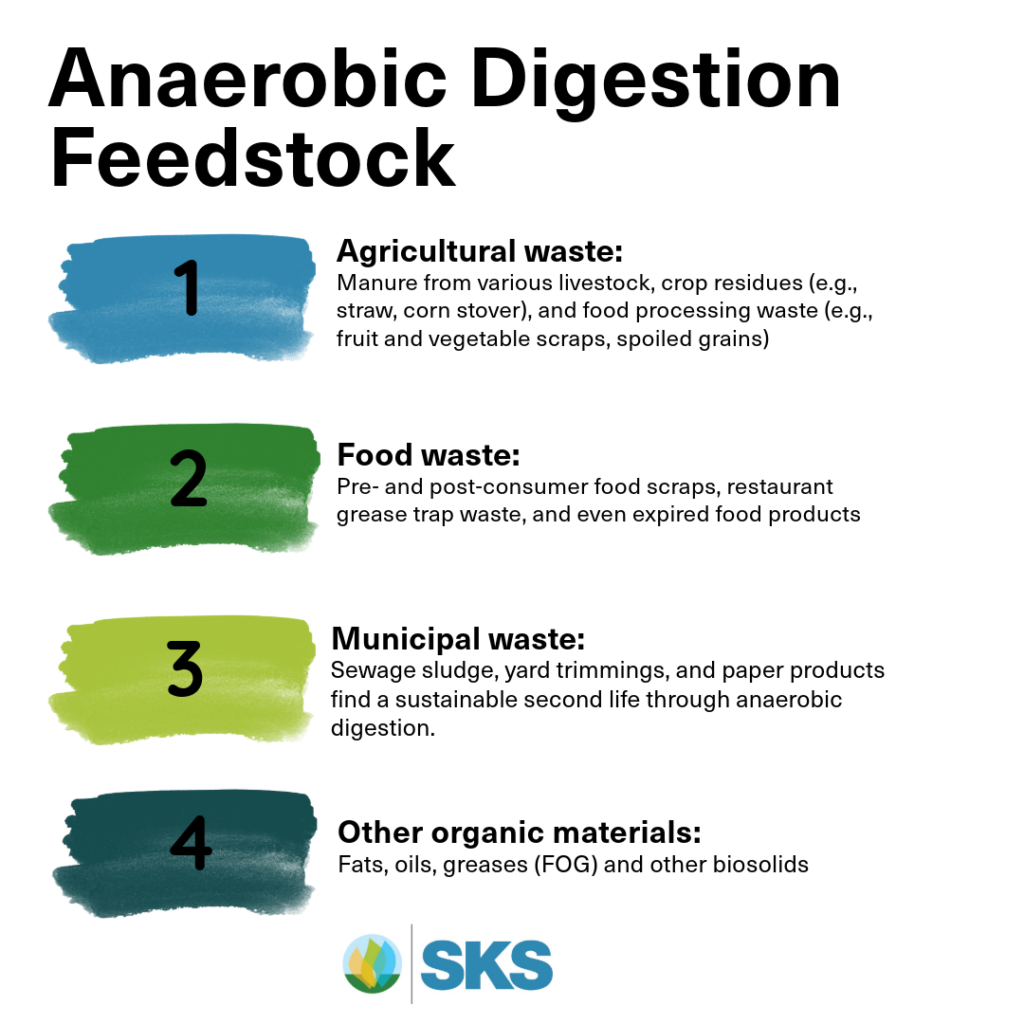

Suitable anaerobic digestion feedstocks include:

- Agricultural waste: Manure from various livestock, crop residues (e.g., straw, corn stover), and food processing waste (e.g., fruit and vegetable scraps, spoiled grains) all contribute valuable biogas potential.

- Food waste: Pre- and post-consumer food scraps, restaurant grease trap waste, and even expired food products can be diverted from landfills and put to good use in the digester.

- Municipal waste: Sewage sludge, yard trimmings, and paper products find a sustainable second life through anaerobic digestion.

- Other organic materials: Fats, oils, greases (FOG) and other biosolids.

Unsuitable feedstocks include:

- Hazardous materials: Chemicals, paints, solvents, and pharmaceuticals pose serious safety risks and can disrupt the delicate digestive processes within the digester.

- Inert materials: Plastics, glass, metal, and rubber offer no biodegradability and can damage digester equipment.

Responsible feedstock selection is key to maximizing the efficiency and longevity of your anaerobic digester. By choosing the right organic materials, you can contribute to a more sustainable and resource-efficient future.

Does anaerobic digestion produce methane?

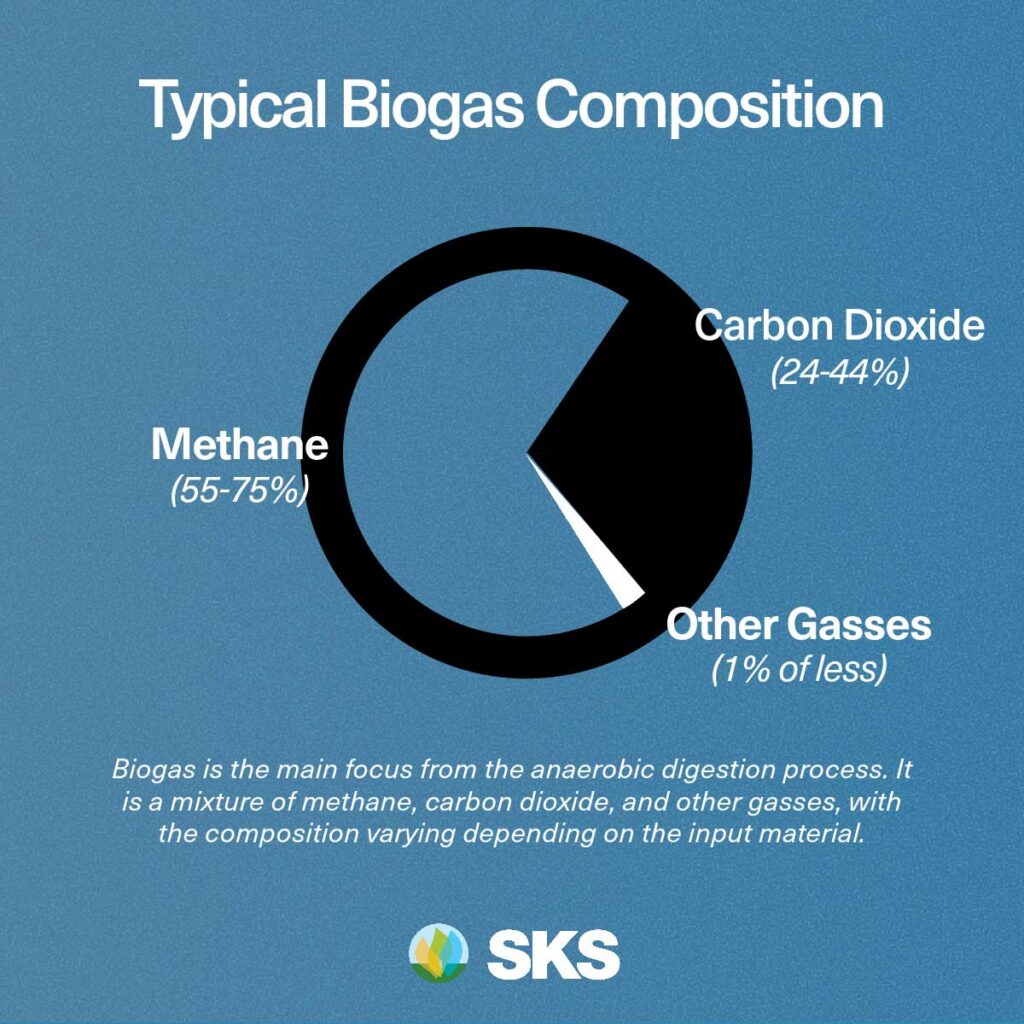

Anaerobic digestion is a powerful tool for converting organic waste into valuable resources, and methane is its key product. In fact, the biogas produced in an anaerobic digester is comprised of 55-75% methane. This renewable fuel boasts a composition similar to natural gas, making it a viable alternative for various applications. The remaining 25-45% of biogas primarily consists of carbon dioxide, with trace amounts of other gasses like hydrogen sulfide and water vapor.

The quantity of methane generated during anaerobic digestion hinges on several key factors:

- Feedstock selection: Different organic materials possess varying biodegradability and potential for methane production. Choosing feedstocks with high methane potential optimizes the process.

- Digester conditions: Temperature, pH, and nutrient balance within the digester play a crucial role in maximizing methane production. Maintaining optimal conditions ensures efficient conversion of organic matter into biogas.

- Digester design and performance: Well-designed and properly maintained digesters deliver superior methane yields. Employing effective technologies and ensuring efficient operation are essential for optimal biogas production.

What is the cost of an anaerobic digester?

The cost of building an anaerobic digester will depend on a number of factors including the size of the facility, the type of feedstock used, and the location of the facility. Review our article on the cost of building a biogas facility to learn more about the major cost components and tips for maximizing operational profitability.

Exploring Anaerobic Digestion for Dairy Farms – A Closer Look

Anaerobic digestion presents a potential path for resource optimization and revenue generation. While its intricacies may appear daunting, this Q&A article has aimed to provide a more objective look at its capabilities and limitations.

Key points to consider:

- Odor Mitigation: While not entirely odorless, anaerobic digestion systems, when properly designed and operated, can significantly reduce emissions compared to traditional waste management methods. Sealed tanks, biodegradation processes, and methane capture technologies play a key role in minimizing unpleasant compounds.

- Environmental Impact: Anaerobic digestion offers a potential avenue for capturing methane and utilizing it for energy production. Additionally, the nutrient-rich digestate produced can be used as fertilizer, potentially reducing reliance on synthetic fertilizers and their environmental impact.

- Feedstock Variety: Anaerobic digestion demonstrates a certain level of flexibility in terms of feedstocks. Manure, crop residues, food scraps, and even sewage sludge can be repurposed as valuable inputs. This adaptability allows dairy farms to explore waste-to-resource possibilities within their operations.

- Biogas Production: Anaerobic digestion yields biogas, a renewable fuel source with various applications. This biogas can be utilized for electricity generation, heat production, or even transportation fuel, potentially offering dairy farms greater energy independence and potentially generating revenue streams.

- Investment Considerations: Initial costs associated with implementing anaerobic digestion can be significant. However, potential long-term economic benefits through energy generation, nutrient recovery, and reduced waste disposal fees should be factored into the decision-making process. Government incentives and grants can also help offset initial costs, making the technology more cost-effective to implement.

In conclusion, anaerobic digestion is a valuable tool for dairy farms seeking to optimize their operations and navigate the evolving agricultural landscape. While its adoption requires careful consideration of its specific benefits and challenges within the context of an individual farm, understanding its capabilities and limitations can empower dairy operators to make informed decisions regarding their future.

For more answers to commonly asked questions about the construction of a biogas facility, visit our FAQs page. If you still have any lingering questions about this process, reach out to the SKS team. We would be happy to answer any questions you have.